Blog

-

25-10-06In the world of industrial piping, where the relentless forces of pressure, vibration, and weight are constant challenges, the integrity of the entire system often hinges on its most fundamental components: the supports and brackets.

-

25-10-01Selecting the optimal material for your gear pump body is a critical engineering decision that goes far beyond a simple catalog choice.

-

25-09-27When specifying an air compressor, attention often focuses on horsepower, CFM ratings, and tank size. However, the material of the compressor housing—the cylinder block and head that contain the pumping cycle—is a critical determinant of long-term performance, reliability, and total cost of ownership. While modern alternatives like aluminum alloys offer lightweight appeal, cast iron remains the ti

-

25-09-22Cast iron valves and cast steel valves differ significantly in terms of material properties, corrosion resistance, applications,and cost.

-

25-09-16With a dedicated foundry and a commitment to engineering excellence, we provide robust, reliable, and durable mooring solutions for demanding marine and industrial applications worldwide.

-

25-09-08Dandong Pengxin Machinery stands as a prominent and fully-integrated foundry and manufacturing specialist based in China, with a proven track record of supplying precision-engineered components to the global energy sector.

-

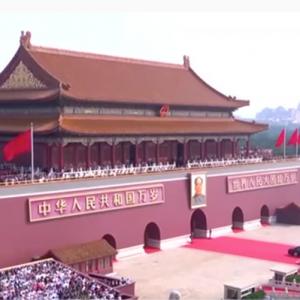

25-09-03To commemorate the 80th anniversary of the victory in the War of Resistance Against Japanese Aggression, Dandong Pengxin organized for all employees to watch the military parade.

-

25-08-30The quickest methods to distinguish between cast iron and cast steel involve visual inspection, sound testing, and simple mechanical checks. Key differences are outlined below

CATEGORIES

LATEST NEWS

CONTACT US

Name: John Yu

Mobile:+86 15941574876

Tel:+86 15941574876

Whatsapp:+86 15941574876

Email:john_yu@metals-casting.com

Add:Wangjiapu Group, Xinan Village, Qianyang Town, Donggang City, Dandong City, Liaoning Province, China.