Blog

Floor Molding from Dandong Pengxin Machinery

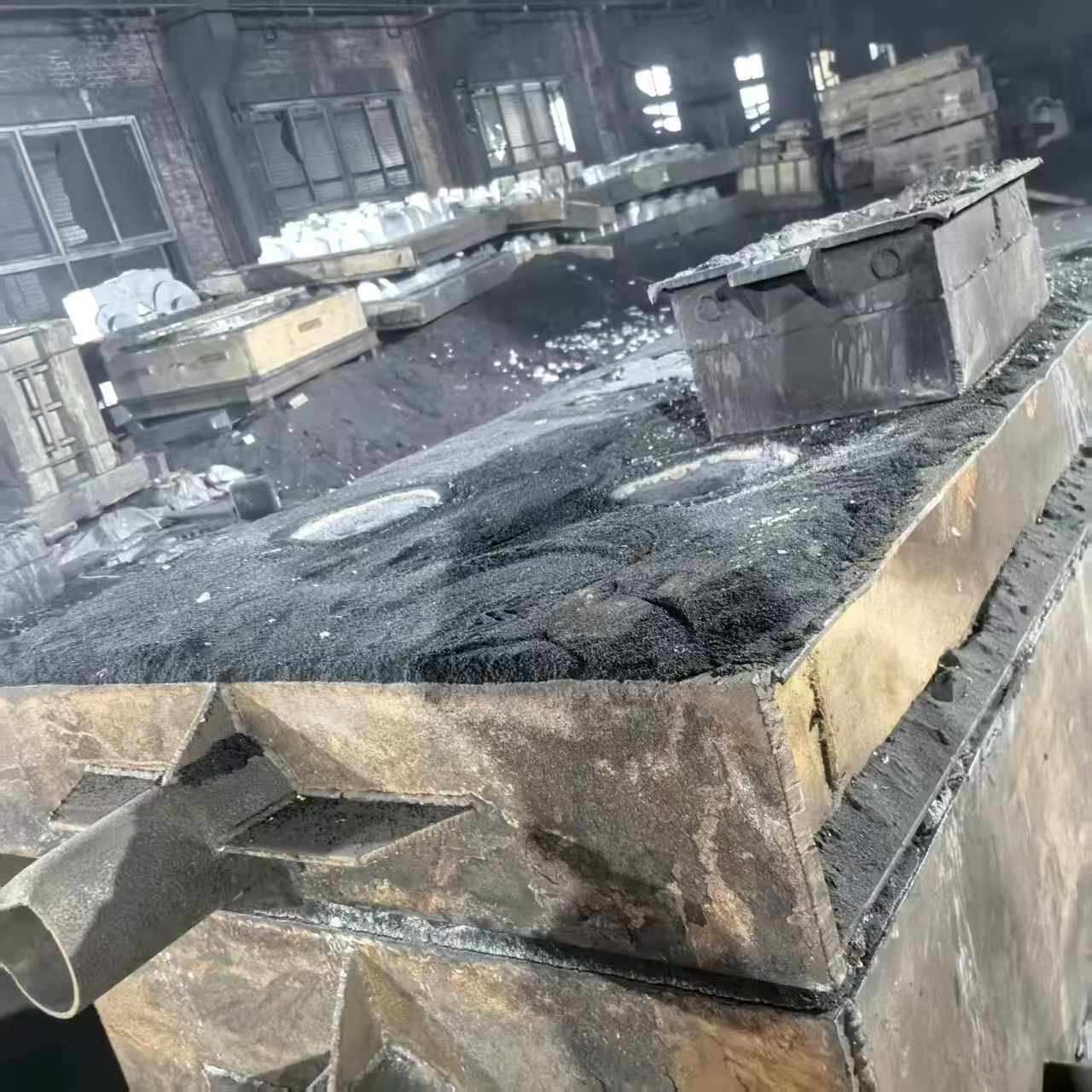

In the dynamic world of metal casting, Floor Molding stands as a cornerstone process, combining traditional craftsmanship with robust engineering. This fundamental sand molding technique involves creating molds directly on the foundry floor using specialized sand boxes, offering unparalleled flexibility and reliability for foundries worldwide.

The Essence of Floor Molding

Unlike automated machine molding, Floor Molding relies on skilled manual craftsmanship to shape molds using either Green Sand (clay-bonded) or Resin Sand (chemically bonded). This hands-on approach provides exceptional control over mold integrity, making it a persistently vital method in both modern Chinese foundries and global casting operations.

Engineering Advantages for Modern Foundries

-

Material Versatility & Cost Efficiency: Utilizing readily available silica sand as the base molding material ensures low production costs and straightforward mold fabrication.

-

Scalable Production: Ideal for low-to-medium volume runs as well as large-scale manufacturing of complex castings.

-

Thermal Management: While standard silica sand meets most needs, specialized sands like Chromite Sand and Corundum Sand are employed for high-temperature applications requiring superior thermal stability.

Binder Systems: The Core of Mold Integrity

The strength of any sand mold lies in its binder system. Floor Molding accommodates diverse bonding agents tailored to specific casting requirements:

-

Clay Binders: The traditional choice for Green Sand Molding, offering excellent collapsibility and reusability.

-

Chemical Binders: Including Furan Resins, Alkali-Phenolic Resins, and inorganic binders like Silicate or Phosphate systems, which provide enhanced dimensional accuracy and surface finish.

-

Oil-Based Binders: Traditional drying oils still serve specialized applications where specific mold properties are required.

This binder classification yields three primary mold types: Wet Clay Sand (Green Sand) Molds, Dry Clay Sand Molds, and Chemically Hardened Sand Molds—each selected based on metal type, casting complexity, and production parameters.

Global Terminology, Universal Application

While regional terminology varies—known as "Green Sand Molding" in many Asian foundries and traditionally as "Floor Molding" or "Floor Moulding" in Western industry standards—the process remains universally recognized for its adaptability and reliability in producing high-integrity castings.

Why Leading Foundries Continue to Choose Floor Molding

As a foundational casting technology, Floor Molding delivers the perfect synergy of economic efficiency, technical flexibility, and proven reliability. It supports the production of everything from simple components to intricate heavy-section castings, maintaining its status as an indispensable method in the global foundry sector.

RELATED NEWS

CATEGORIES

LATEST NEWS

CONTACT US

Name: John Yu

Mobile:+86 15941574876

Tel:+86 15941574876

Whatsapp:+86 15941574876

Email:john_yu@metals-casting.com

Add:Wangjiapu Group, Xinan Village, Qianyang Town, Donggang City, Dandong City, Liaoning Province, China.