Dorman 674-988 Passenger Side Exhaust Manifold Kit

- Category: Exhaust Manifold

- Material: grey cast iron

- Production process:shell casting

- Inspection: 100% inspection before shipping

- Mold Material:Metal

Product Detail

|

OE NO. |

1162773452343 |

Condition |

Condition |

|

Warranty |

12 month |

Place of Origin |

Liaoning, China |

|

Car Model |

OEM |

Purpose |

For manufacturing |

|

Reference NO. |

T435100, 0810152, 0810184, 0011021779, 180406SET |

Size |

According your customs |

|

Brand Name |

OEM |

Model Number |

Copy according your sample or drawing |

|

Material |

Gray Cast Iron,Ductile Iron,Stainless Steel,Aluminum |

Production Process |

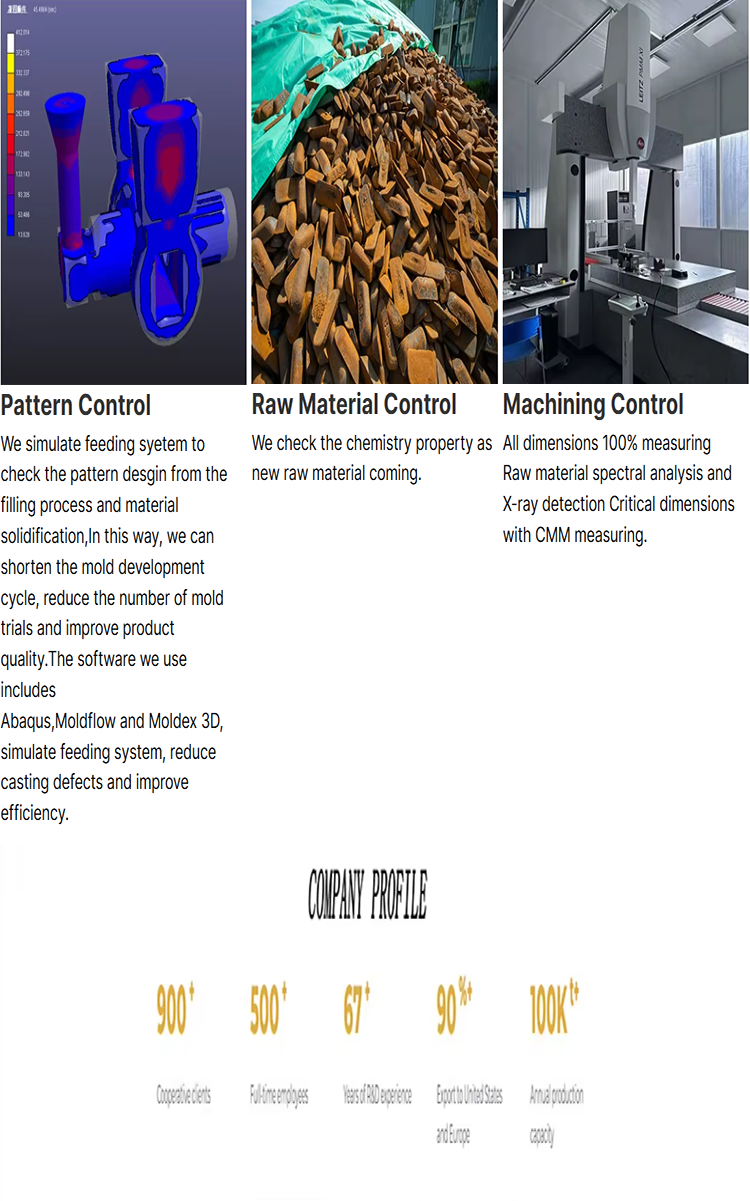

Resin-Coated Sand,Sand Casting |

|

Surface Treatment |

Black spray paint, ceramic coating, electrolytic polishing |

How to Make The Production |

According your sample or drawing |

|

Moq |

1 Piece |

Packing |

Carton Package |

|

Delivery time |

7-15days |

Our Experience |

More than 20 years |

|

Why are we called OEM experts in Exhaust Manifolds |

We develop over 100 different types of exhaust manifolds every year |

|

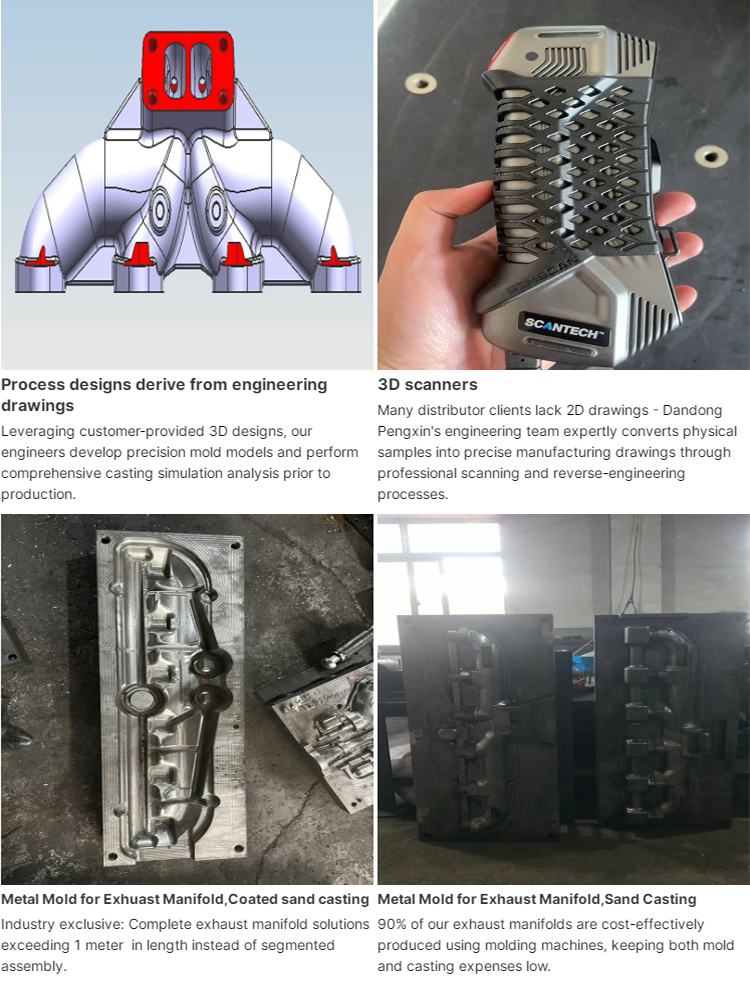

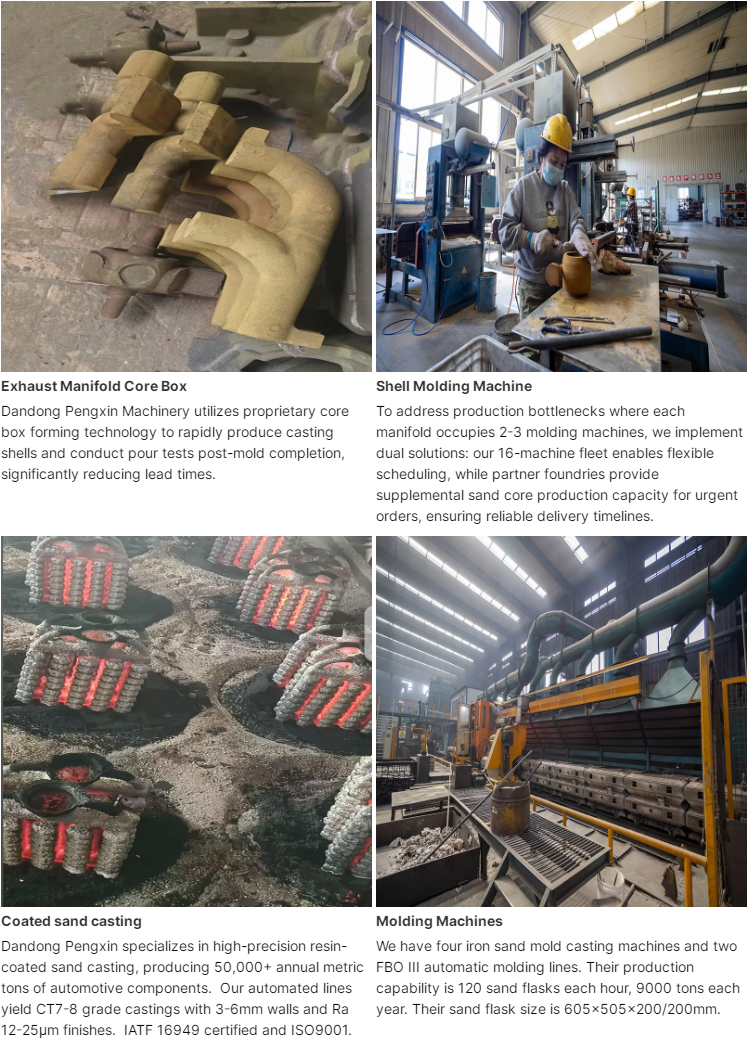

Dandong Pengxin Production Process for Exhaust Manifold |

Drawing Preparation: The Foundation of Precision,3D Scanning & Drafting: Our professional engineers use advanced scanners to convert samples into 2D/3D drawings (7–10 days). |

|

Pattern & Sample Development: Where Time Invested Pays Off |

Complexity: Exhaust manifolds often require 3–5 sets of metal patterns (vs. 1 set for simpler castings).Lead Time: 35–40 days for multi-cavity patterns; 25–30 days for simpler designs. |

|

Initial Orders & Batch Production: Scaling Responsibly |

Machine Allocation: One manifold order may occupy 2–3 molding machines. Our 16-machine facility prioritizes urgent orders and collaborates with partner foundries for auxiliary cores. |

|

How Investors Can Mitigate Delays |

Allocate 8–12 weeks for pattern/sample development. Compressing this risks quality failures. First batches take 20–30% longer due to process fine-tuning. Post-approval, lead times stabilize. |

Service

Pre-Sales

Get your purchasing needs → Confirm order drawing→ Give customized solution → Offer a quotation → Make the pattern→ Provide samples→ Bulk production after samples approve the test.

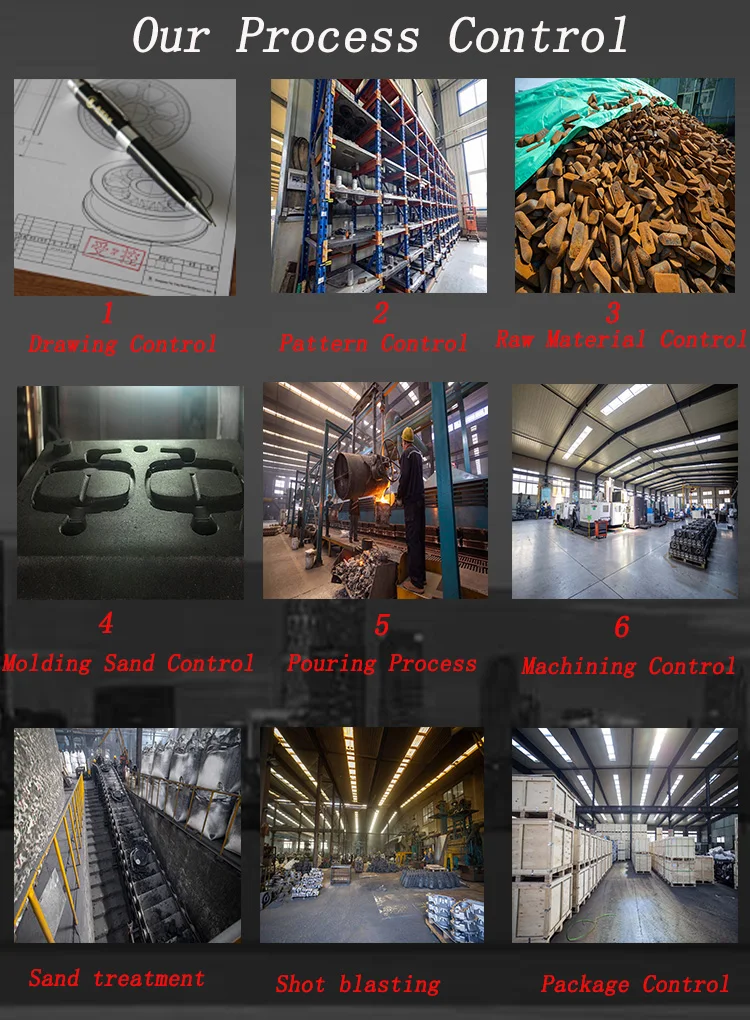

On Sale

Drawing Control → Pattern Control → Raw Material Control → Molding Sand Control → Pouring Process Control → Raw Casting & Machining Control →Other Requirement Control→ Packing & Delivery Control.

After-Sales

Proactively get your feedback→ Engineering team gets involved→Casting engineer conducts metallographic and spectral tests based on the inventory test rods→Machining engineer's CMM inspection is based on the inventory samples→Provide solutions based on the test results→Welcome to contact us for your customized solution.

Why choose us

How did Dandong Pengxin Become a Top Manufacturer of Exhaust Manifold

To become a world-leading exhaust manifold producer, Dandong Pengxin Machinery introduced in advanced manufacturing technologies, material innovation, quality control, and supply chain efficiency. Below are the key strategies to achieve this goal.

(3)Gravity Casting for Aluminum Manifolds

Lightweight solutions for hybrid/electric vehicle exhaust systems,Gravity casting is the preferred method for mass-producing exhaust manifolds, involving melting metals like cast iron or aluminum and pouring the molten material into preheated steel molds solely by gravitational force. The process naturally fills mold cavities without external pressure, though some advanced variants may apply minimal supplemental pressure (0.2-0.5 bar) for complex geometries. This cost-effective method yields components with uniform 3-6mm wall thicknesses and smooth surfaces, offering superior metallurgical integrity and higher production rates than sand casting, making it ideal for durable exhaust systems requiring consistent quality in high volumes.

2.Quality & Certification Standards

ISO 9001/TS 16949 (IATF 16949) → Automotive quality compliance.

Leak & Pressure Testing → Ensures 100% gas-tight manifolds.

Thermal Cycling Tests → Simulates 10+ years of thermal fatigue.

3D Scanning & CMM Inspection → Validates dimensional accuracy (±0.1mm).

Our Factory strength display

R&D

Our Company Owns A Provincial Level Technology Center, Plus A 15 Person R&D Team, With average 20+ Years Of R&D Experience. We can help customers design for free according to their requirements, or produce according to the drawings or samples.

Production Capacity

At Pengxin-Casting, process control begins as early as in the planning and development phase of the products. We support our customers to perform all required tests and inspections in a laboratory. It goes without saying that our plants are certified according to ISO 9001 and IATF16949 in line with a validated quality management. As we strive to accomplish our zero-error policy,you can rely on the following process control measures: Drawing Control → Pattern Control → Raw Material Control → Molding Sand Control → Pouring Process Control → Raw Casting & Machining Control →Other Requirement Control→ Packing & Delivery Control.

Our Process Control

Our Team

Dandong Pengxin Foundry - Your Trusted Casting Solutions Partner Backed by 67+ years of metallurgical expertise, we deliver precision castings including exhaust manifolds and turbo housings through advanced resin-coated sand and gravity casting technologies. Our 50,000-ton capacity facility features automated molding machines, robotic shell production, and spectral analysis for quality assurance, serving global automotive and industrial clients with IATF 16949-certified manufacturing. Specializing in thin-wall (3-6mm) castings with Ra12-25μm finishes, our engineering team develops optimized solutions from prototype to mass production, supported by in-house mold design and rapid sample development within 15 days.

CATEGORIES

LATEST NEWS

CONTACT US

Name: John Yu

Mobile:+86 15941574876

Tel:+86 15941574876

Whatsapp:+86 15941574876

Email:john_yu@metals-casting.com

Add:Wangjiapu Group, Xinan Village, Qianyang Town, Donggang City, Dandong City, Liaoning Province, China.